The idea of autonomous maintenance is to give operators more responsibility and allow them to carry out preventive maintenance jobs. Autonomous maintenance was not the result of a desire to reduce maintenance costs or maintenance departments wishing to hand over maintenance tasks to production, rather it was the result of production teams wishing to control and improve their equipment.

Autonomous Maintenance is the first step in the process of implementing Total Productive Maintenance. In real-time, this means that simple actions like minimum safety checks, inspection, cleaning, and lubrication, are performed by operators of that asset, which gives maintenance technicians the freedom to concentrate on more complex maintenance tasks.

Autonomous maintenance helps in observing issues before they lead to critical breakdowns. It helps in refining employee participation and a sense of relevance in the bigger picture.

Konstruct ltd. is a construction company that manages a fleet of heavy dumpers. Konstruct ltd uses these heavy dumpers in all its construction projects. The heavy dumpers require regular maintenance and upkeep to ensure they are in good working condition and the operation of the business is not interrupted. While managing a fleet of heavy equipment can otherwise be quite a daunting task, using R.M.R. for the job can make the whole process simple and manageable.

Repair. Maintain. Rent. (R.M.R.) is an asset management suite in Ax2012 and D365 which helps businesses to set up autonomous maintenance.

Konstruct ltd. has a fleet of dumpers and the resources operating those dumpers are trained to do autonomous maintenance.

Let’s do a quick recap of the required setup in R.M.R.

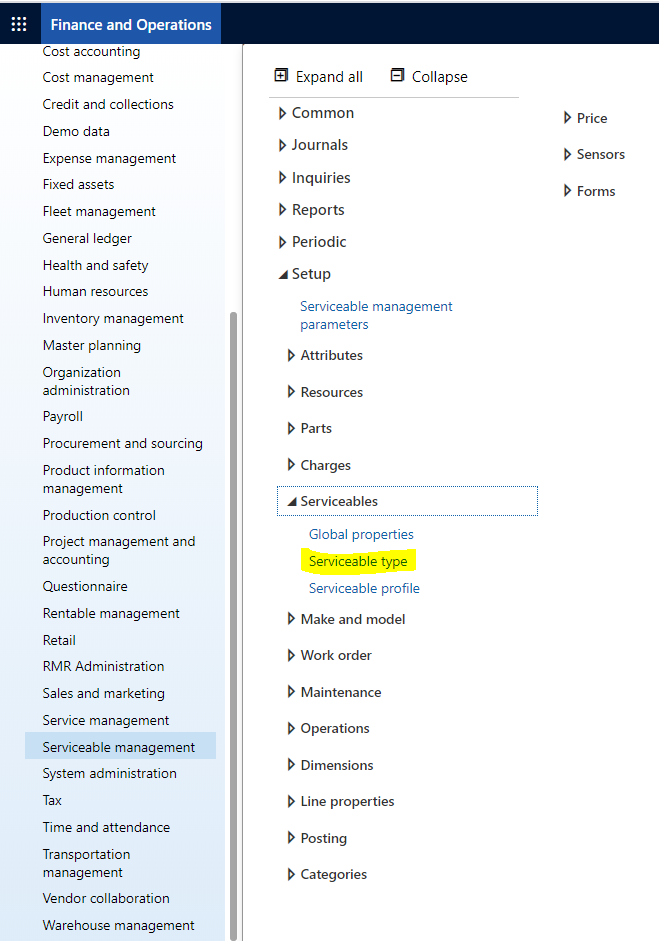

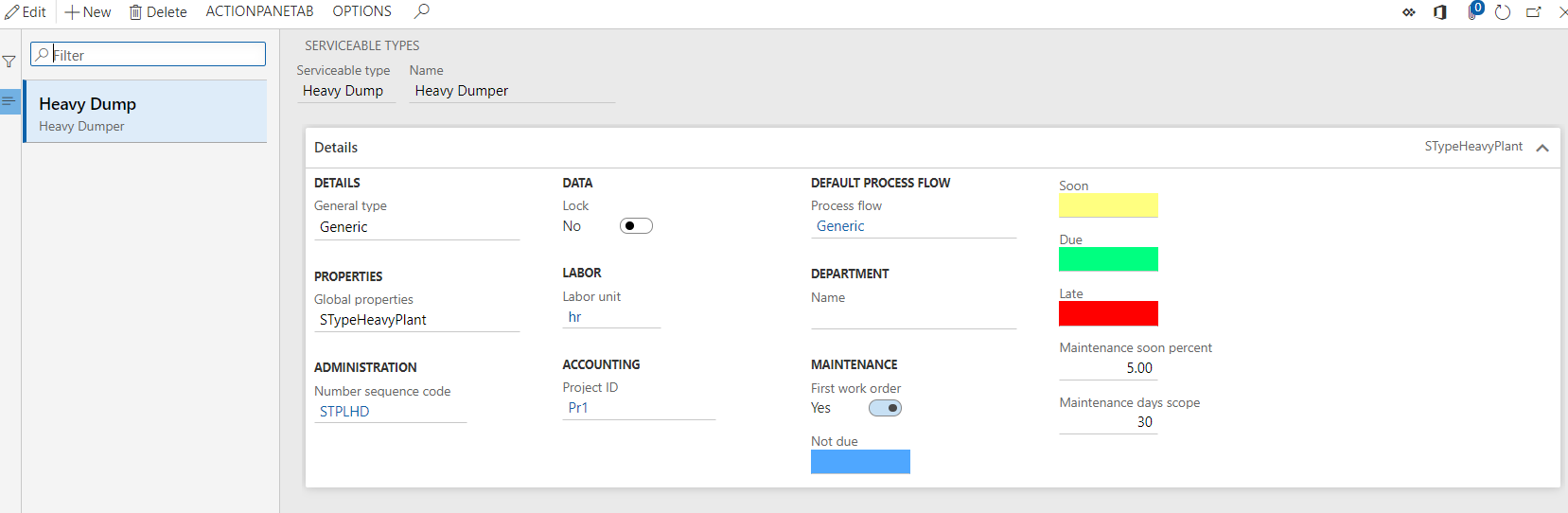

Serviceable management >Setup> Serviceable type:

Serviceable type mainly refers to the industry type to which serviceable belong. It is a broader categorization of assets. Serviceable is nothing but Assets in R.M.R.

To know more about the serviceable type, refer our R.M.R. blog on Managing your company’s assets with Repair. Maintain. Rent.

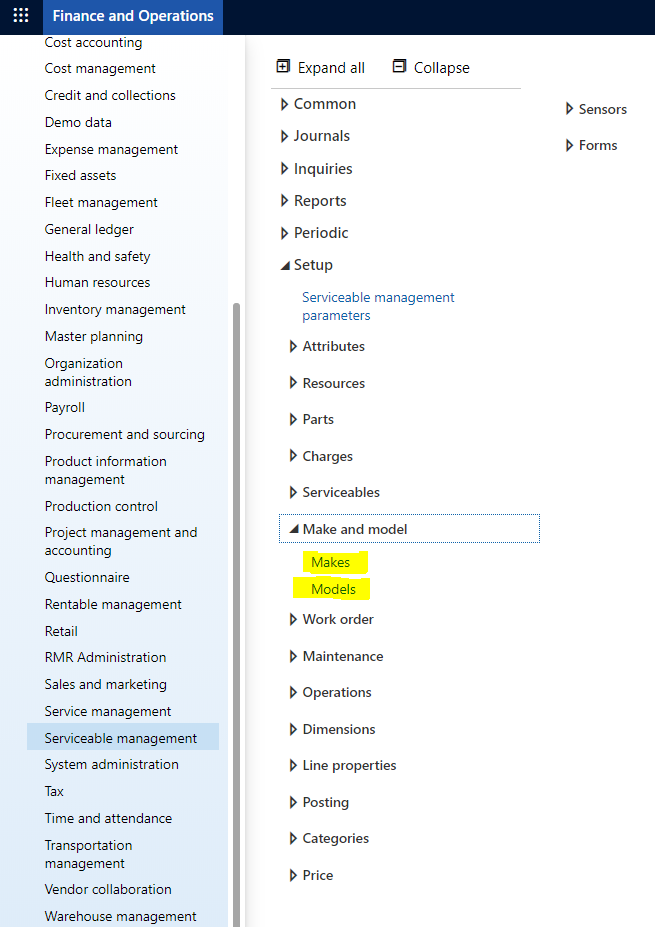

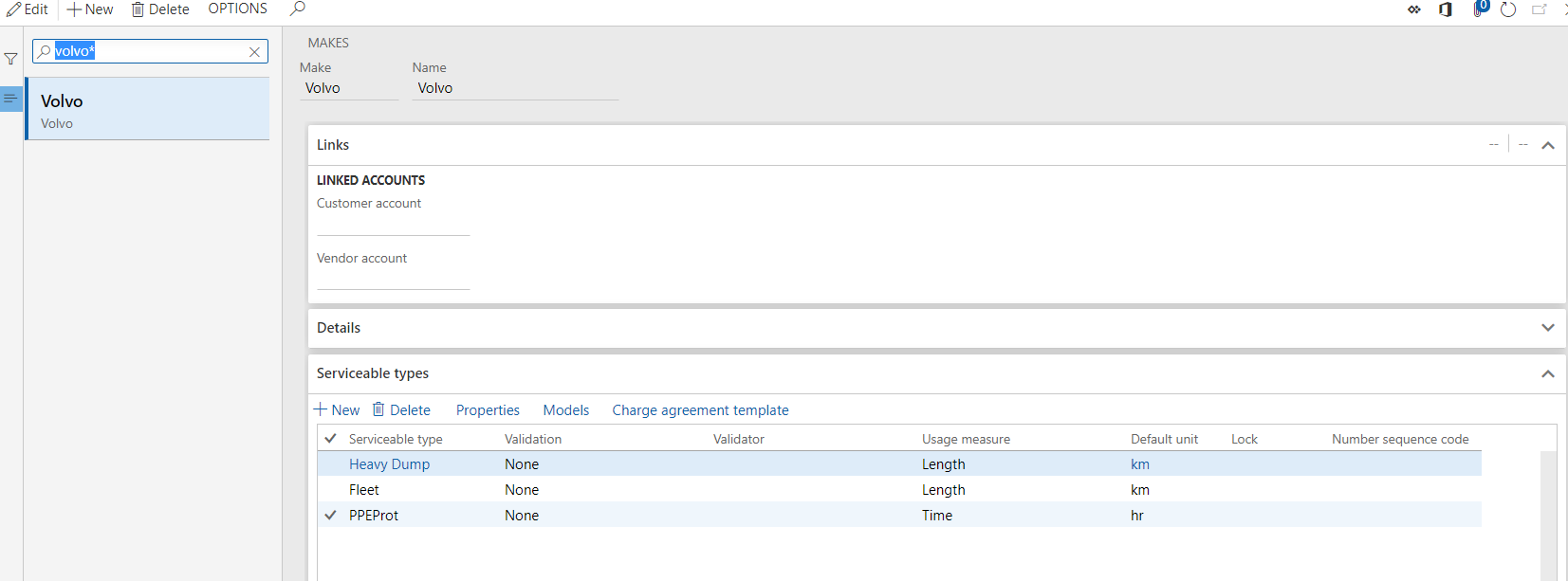

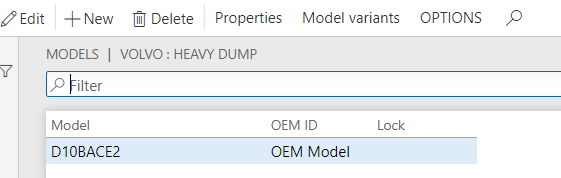

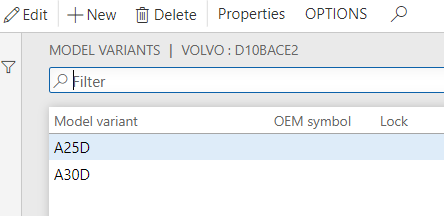

Serviceable management >Setup> Make and Model

To know more about make and model, please refer R.M.R. blog on Managing your company’s assets with Repair. Maintain. Rent.

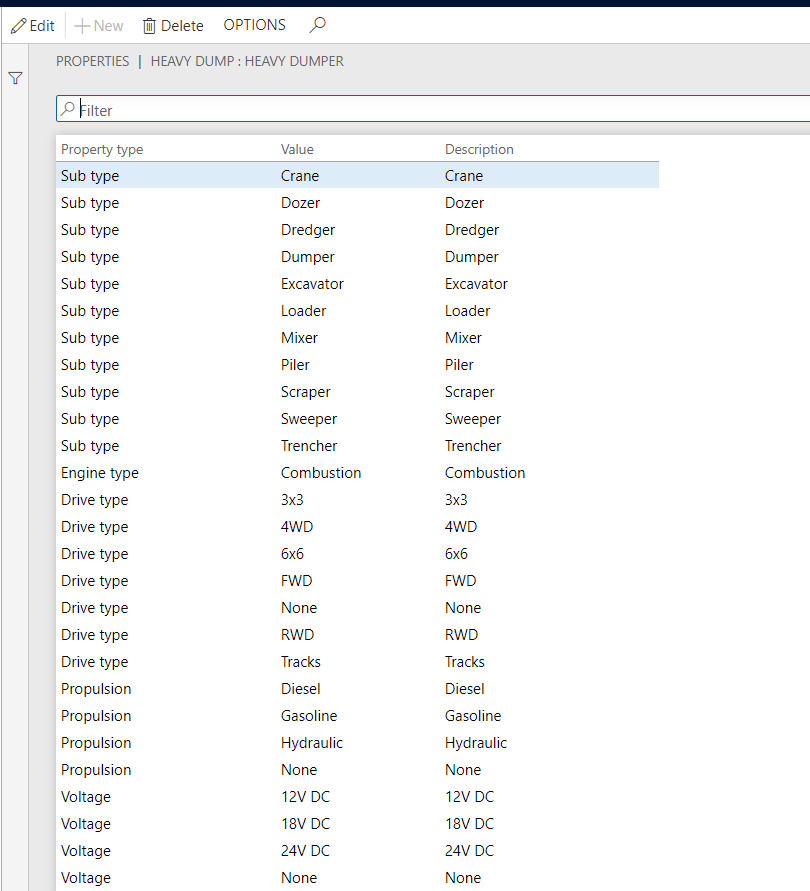

Create appropriate properties for the serviceable type.

To know more about global properties, please refer R.M.R. blog on Managing your company’s assets with Repair. Maintain. Rent.

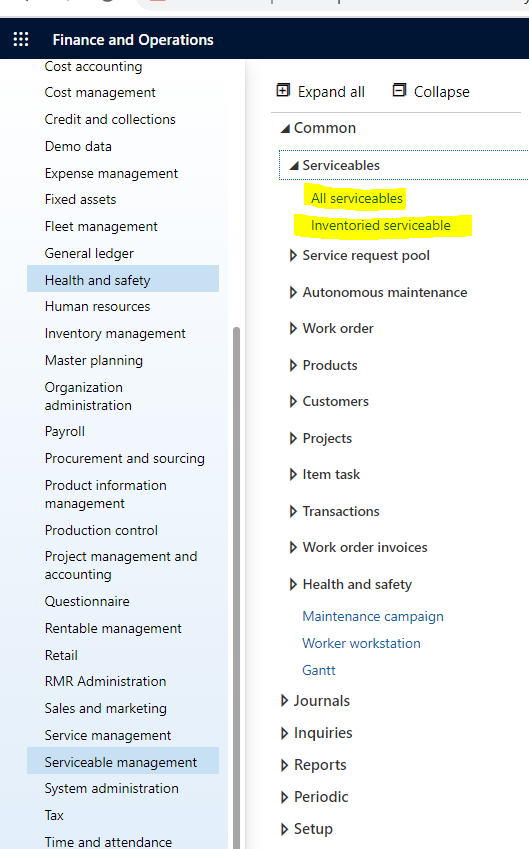

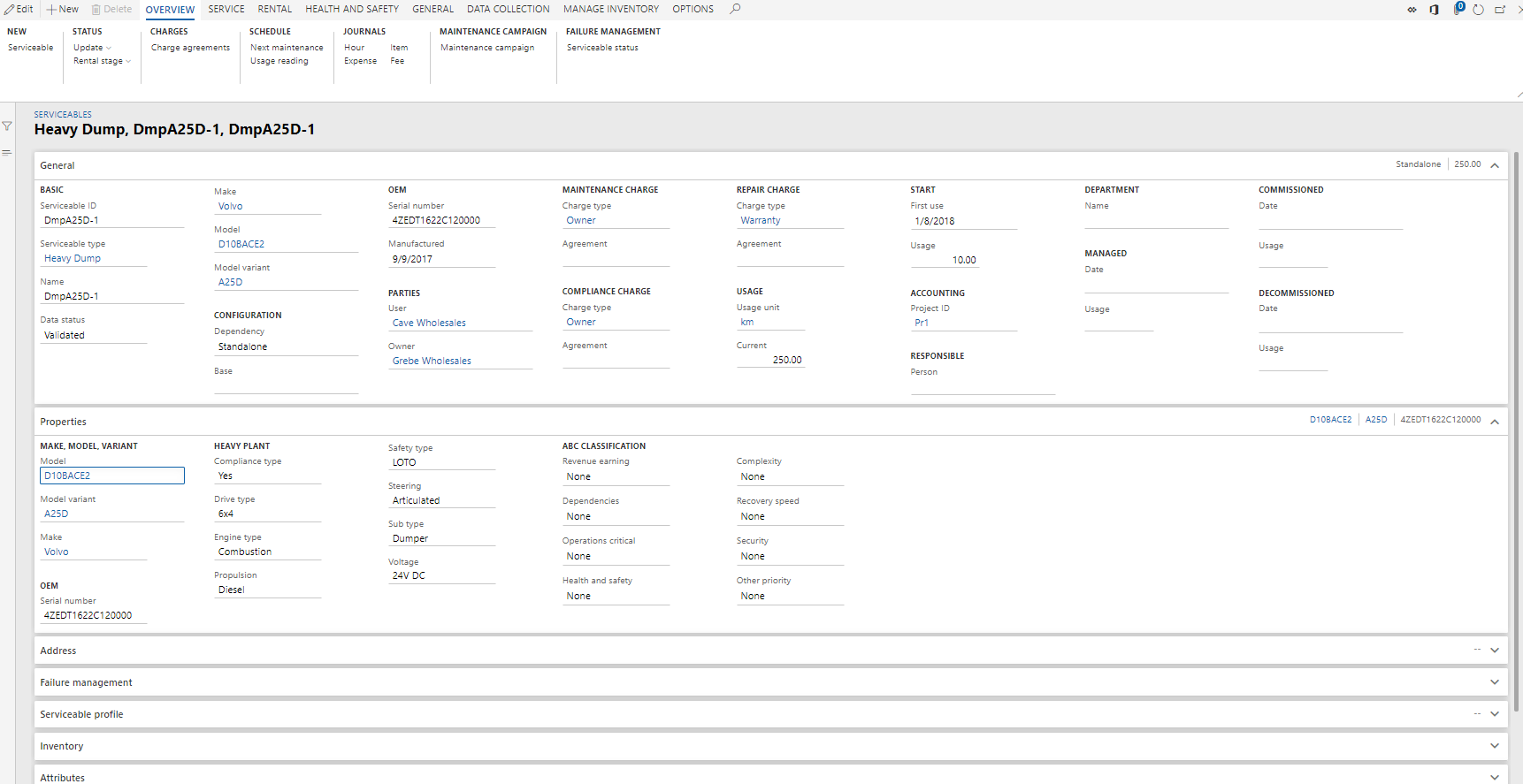

Create all the required Serviceable (Assets)

Serviceable management > Common > All Serviceables.

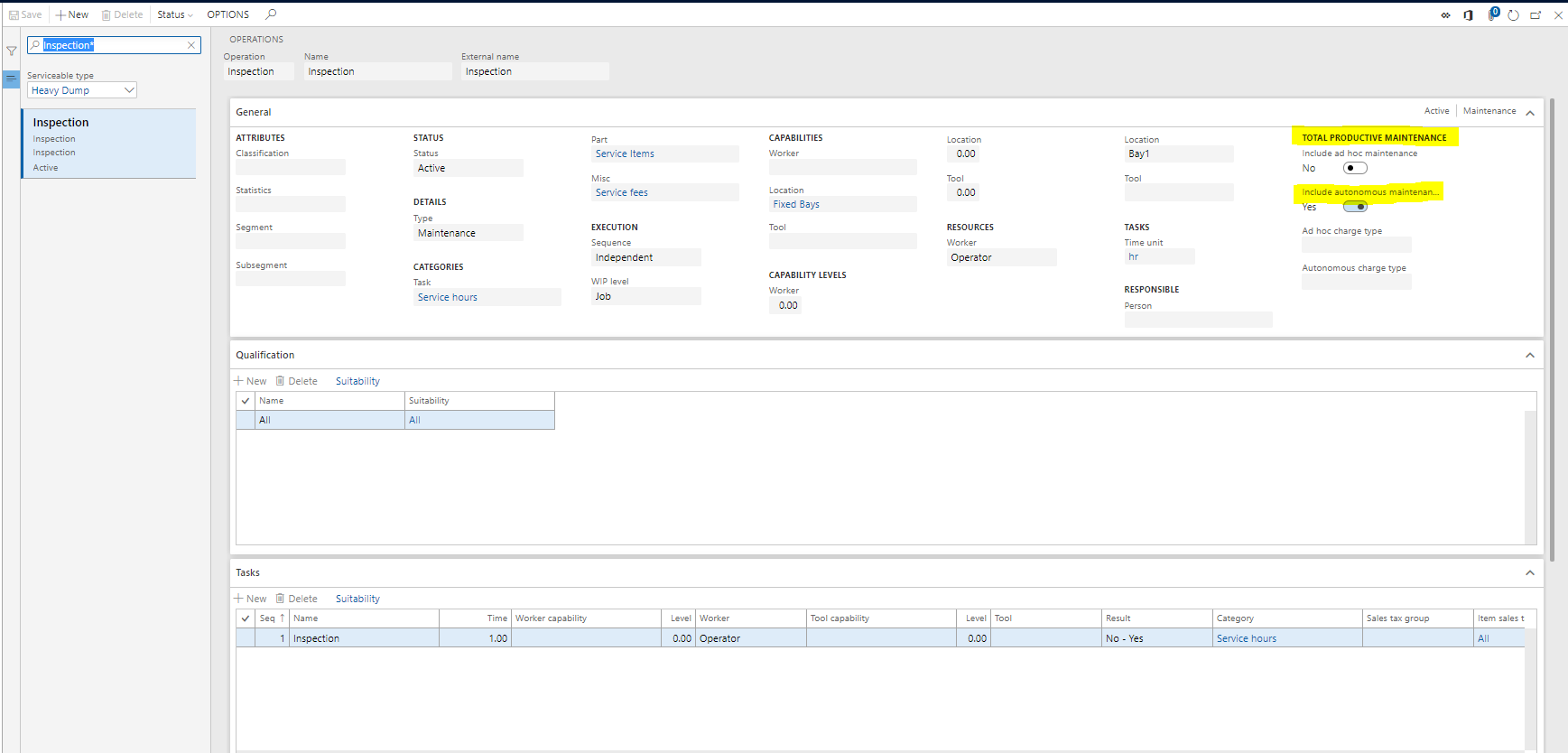

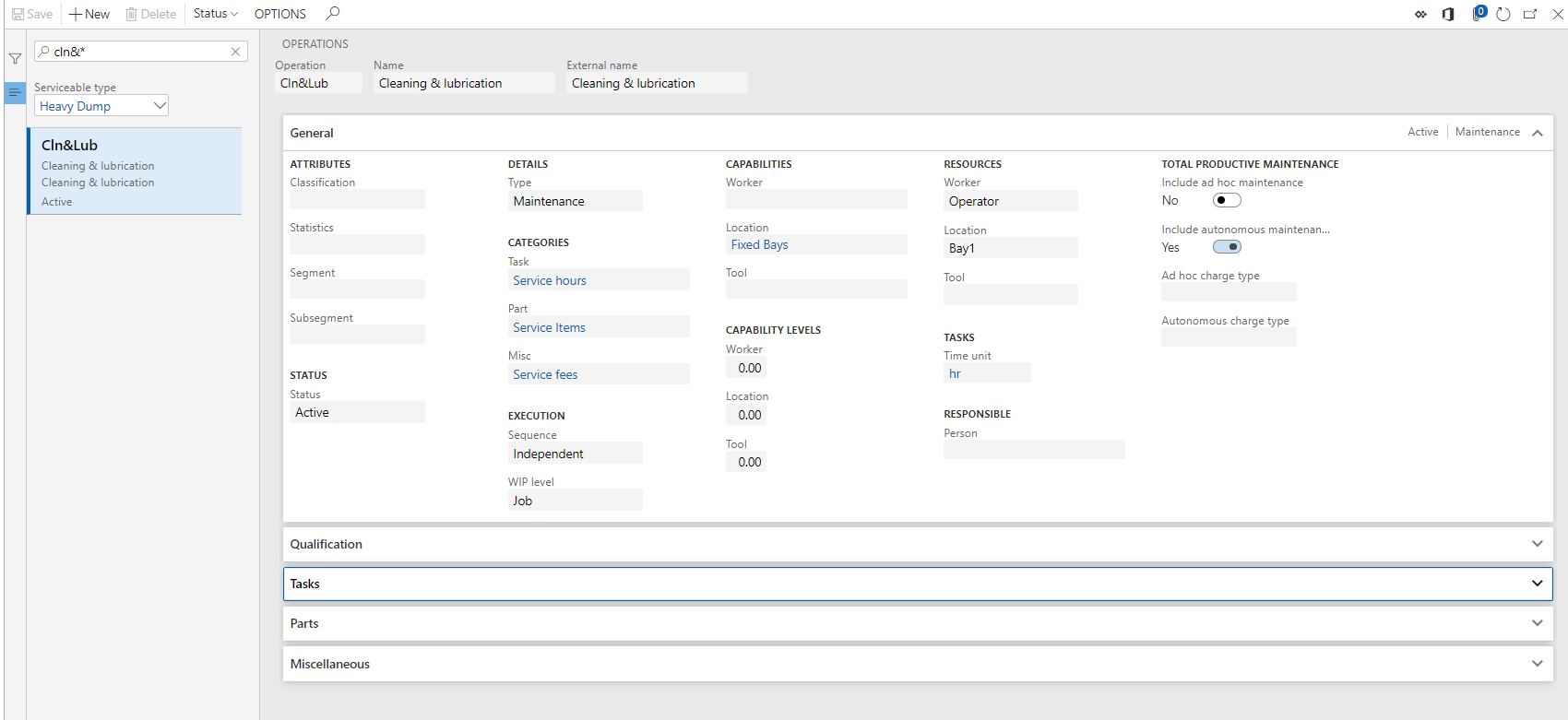

Identify the operation to be used in Autonomous work orders by marking autonomous maintenance against the operation for the serviceable type HDumper (Heavy dumper).

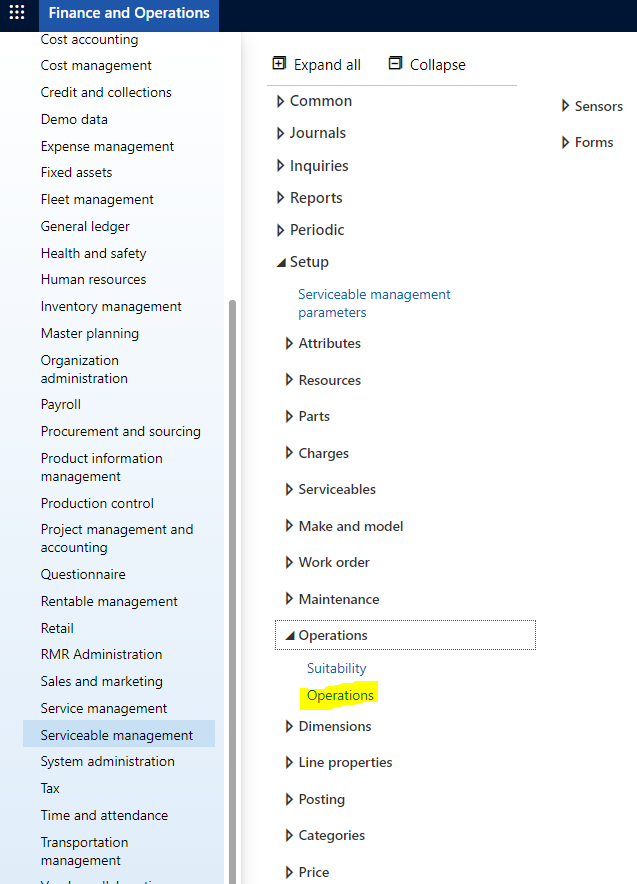

Serviceable management > Setup> Operations>Operations.

Create a new operation called Inspection.

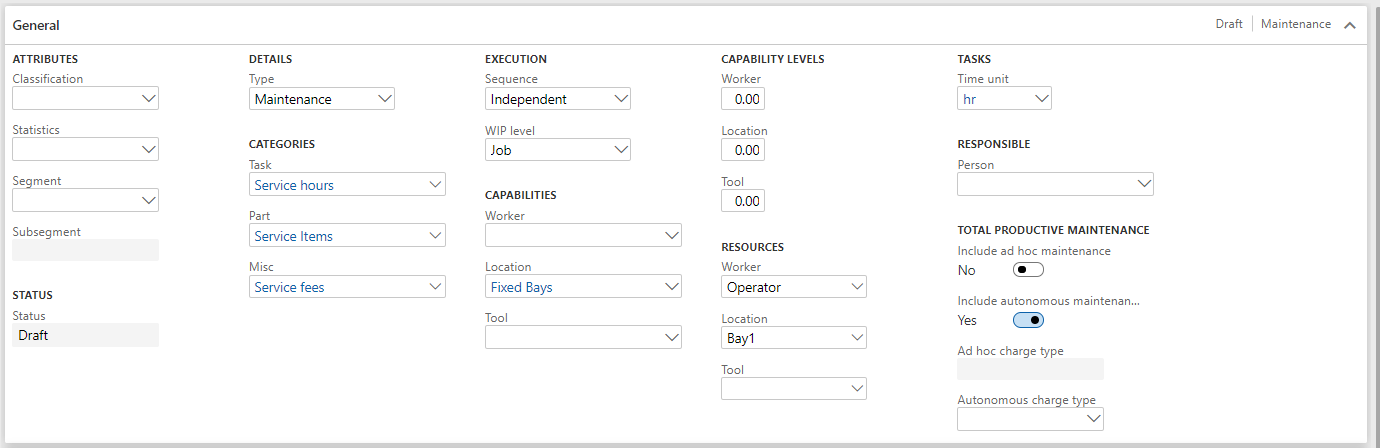

Assign the categories

Assign location

Assign worker: Operator

Enable ‘Include autonomous maintenance’ under Total productive maintenance.

When you enable the autonomous maintenance, the following message will trigger ‘The parts and miscellaneous fee will not be considered for autonomous jobs.

Assign suitability

Create a task (Hour) ‘Inspection’ with the time as 1 and suitability as All.

Activate the operation

Create another operation called cleaning and lubrication in the same way as mentioned above.

Once the Operations (jobs) are created we are now ready to create an Autonomous work order.

Let’s say in this case the operator must inspect the tyres, air, lubrication levels before he starts the workweek. And In case of any discrepancy, he is trained to fix them.

In order to do that, the operator can create an Autonomous work order.

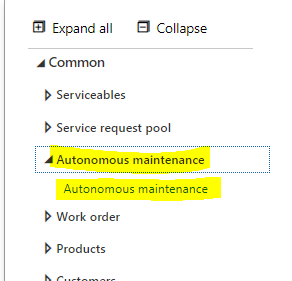

Serviceable management > Common> Autonomous maintenance> Autonomous maintenance.

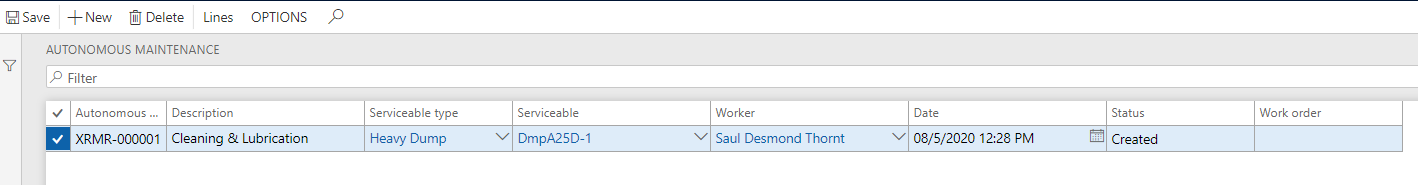

Click on New, give the description, add the Serviceable type (asset type), add the Serviceable (asset), and the operator under the worker.

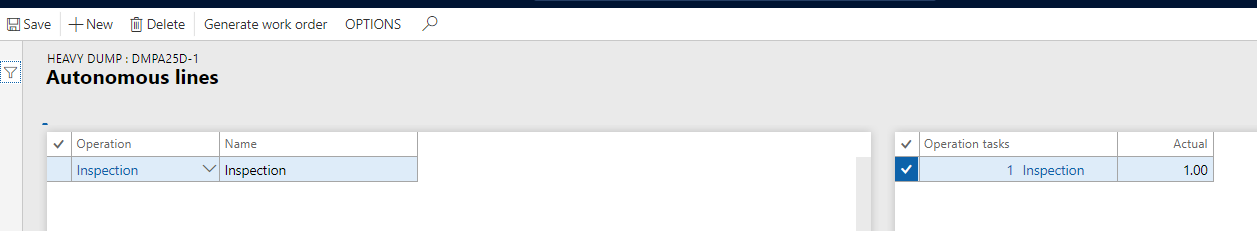

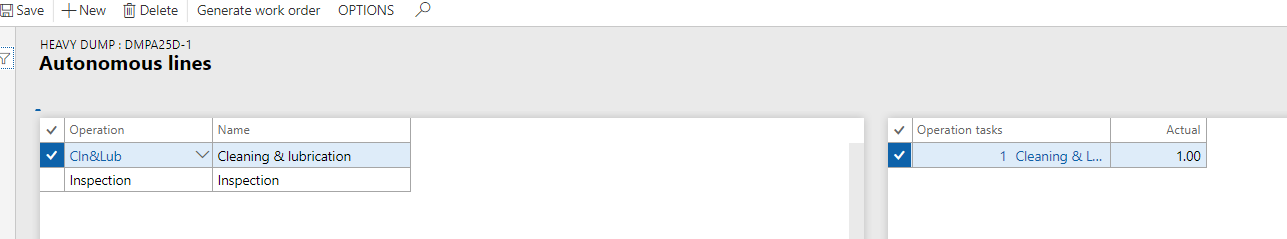

Click on the lines button and select the operation ‘Inspection’. The operation drop-down will show only those operations which are autonomous maintenance enabled. Once the inspection is complete, he can update the time in the actuals as shown in the screenshot below.

Now in case, the Operator finds that lubrication is required, he will add another operation called cleaning and lubrication and will enter the actual time taken once the work is complete.

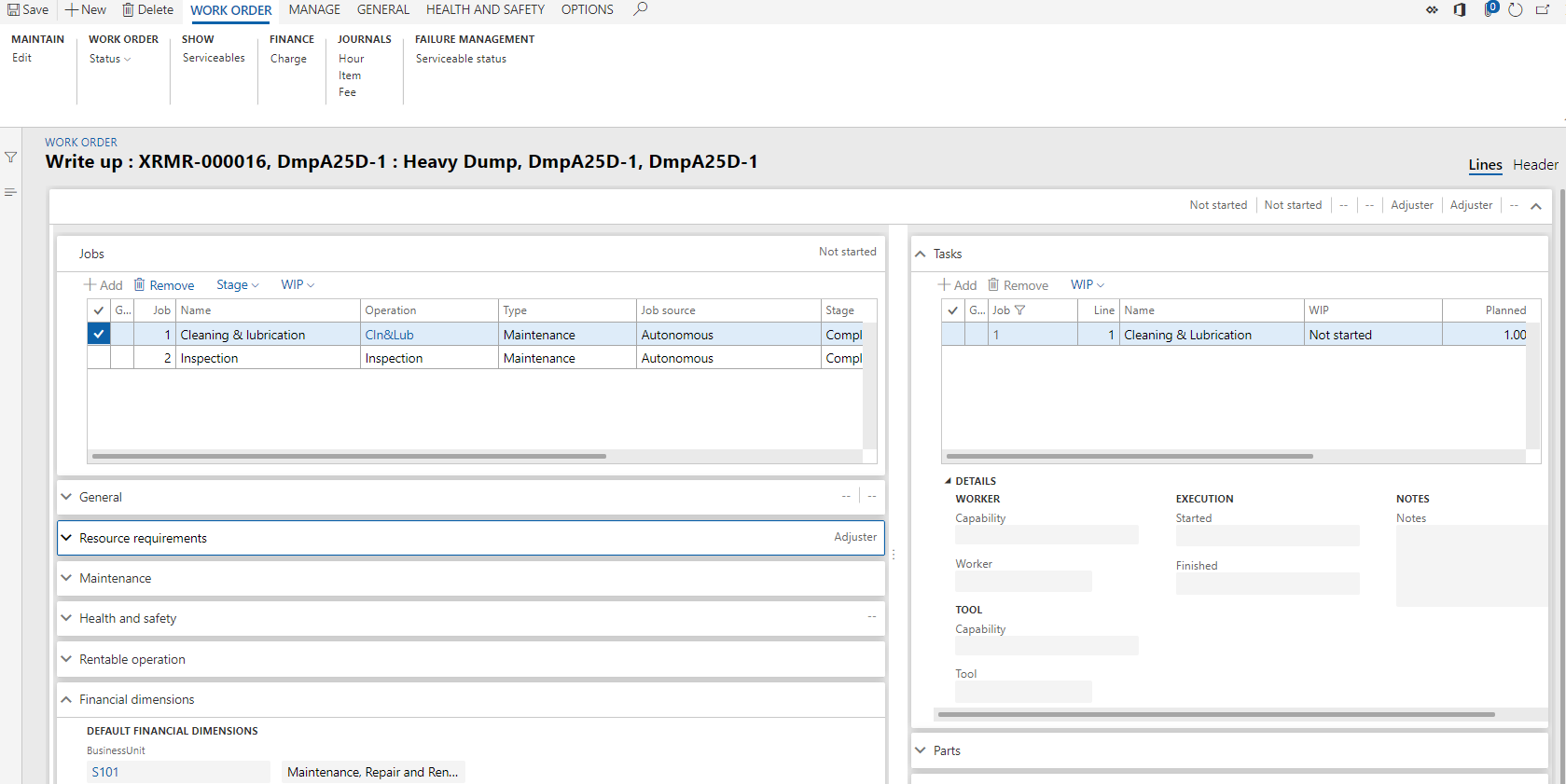

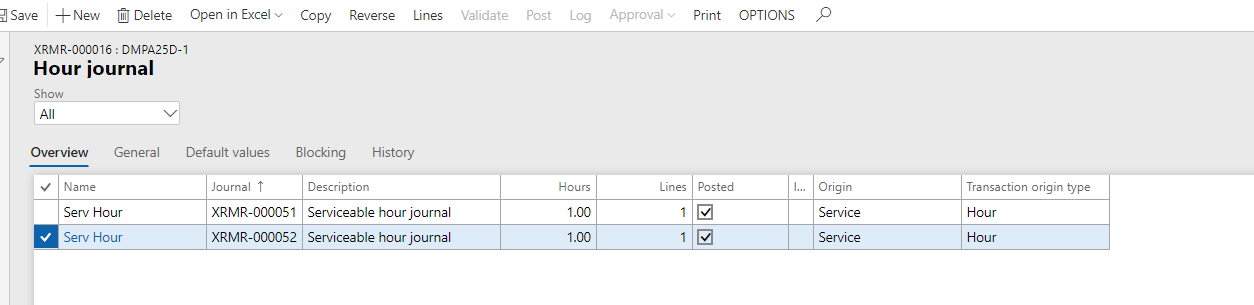

Once the updates are complete, the operator can click on Generate Work order, and required cost journals are posted automatically.

Hour journals are posted.

The entire process is simple and cost-effective. For more such insights on R.M.R.

Author

Rohan Wilson Lobo